TENNIS BALL FELT

Feirong Felt Factory Producing

Feirong Tennis Felt Factory, a subsidiary of Wuxi Feirong Sporting Trade Co., Ltd., was established in 2005. The factory was initially set up to complement the tennis ball production line introduced from Nassau, a leading South Korean tennis brand. The felt was primarily produced for in-house use. We even produced tennis balls for Head for shipments. In 2018, our focus shifted from in-house felt production to supplying the domestic and international markets.

The Tough Issue of Mold Seams

The molding seams on 100% polyester felt tennis balls formed during the curing process, are more or less difficult to completely eliminate after the fluffing process. Feirong Felt Factory, leveraging 20 years of felt production and R&D, has recently overcome this technical challenge. The mold seams on polyester felt tennis balls will no longer trouble the tennis ball manufacturers.

The Balls After Curing

The Balls After Fluffing

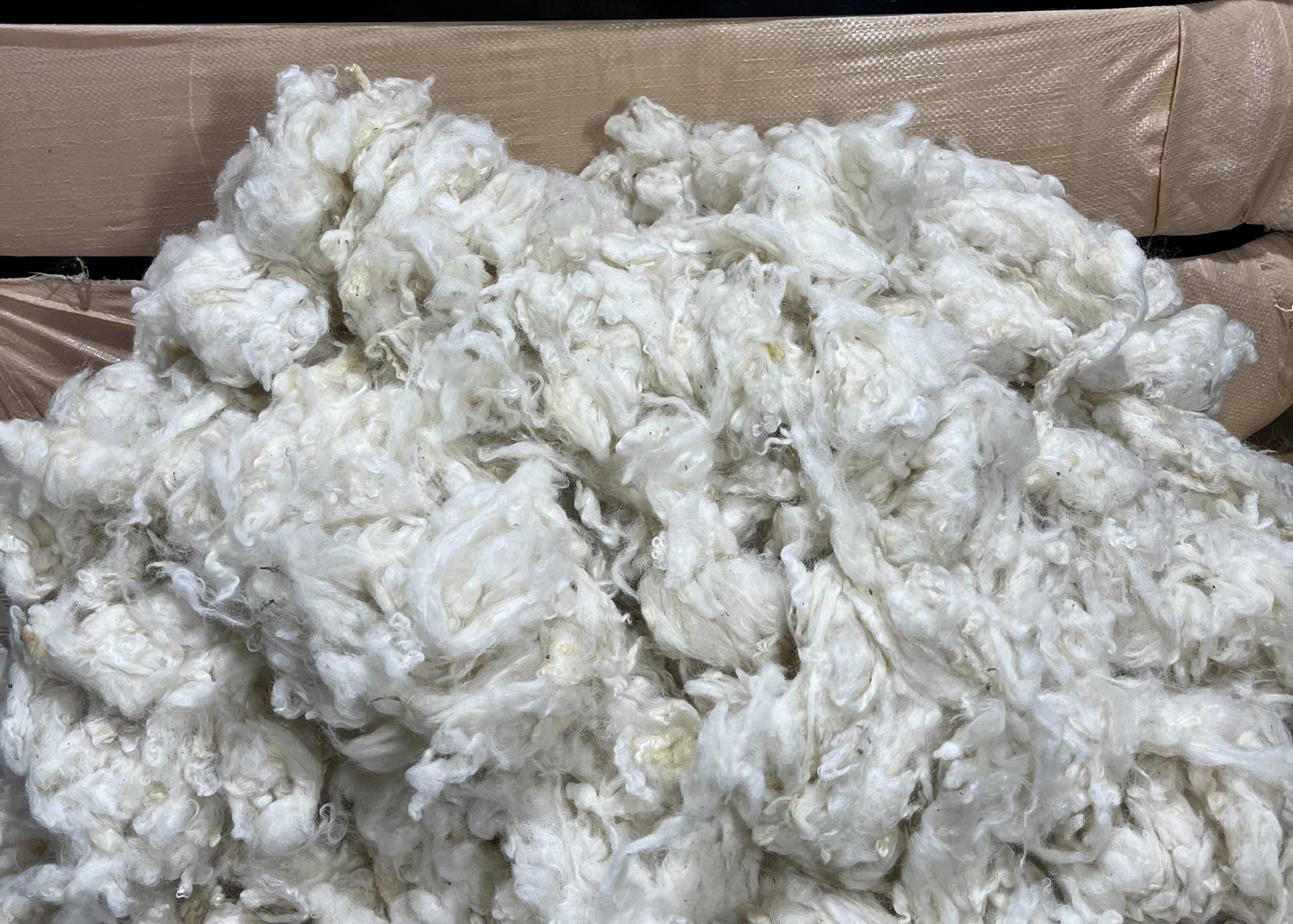

Raw Material

Naturel Fiber

Imported wool to meet the advanced property requirements for tennis balls

Chemical Fibers

Nylon, acrylic, and polyester etc. to meet the demand for different types of balls

Full Range of Colors

To meet the appearance requirements of different types of tennis balls

Production Line

Blending Process

Felts of different specifications are blended with fibers in varying proportions

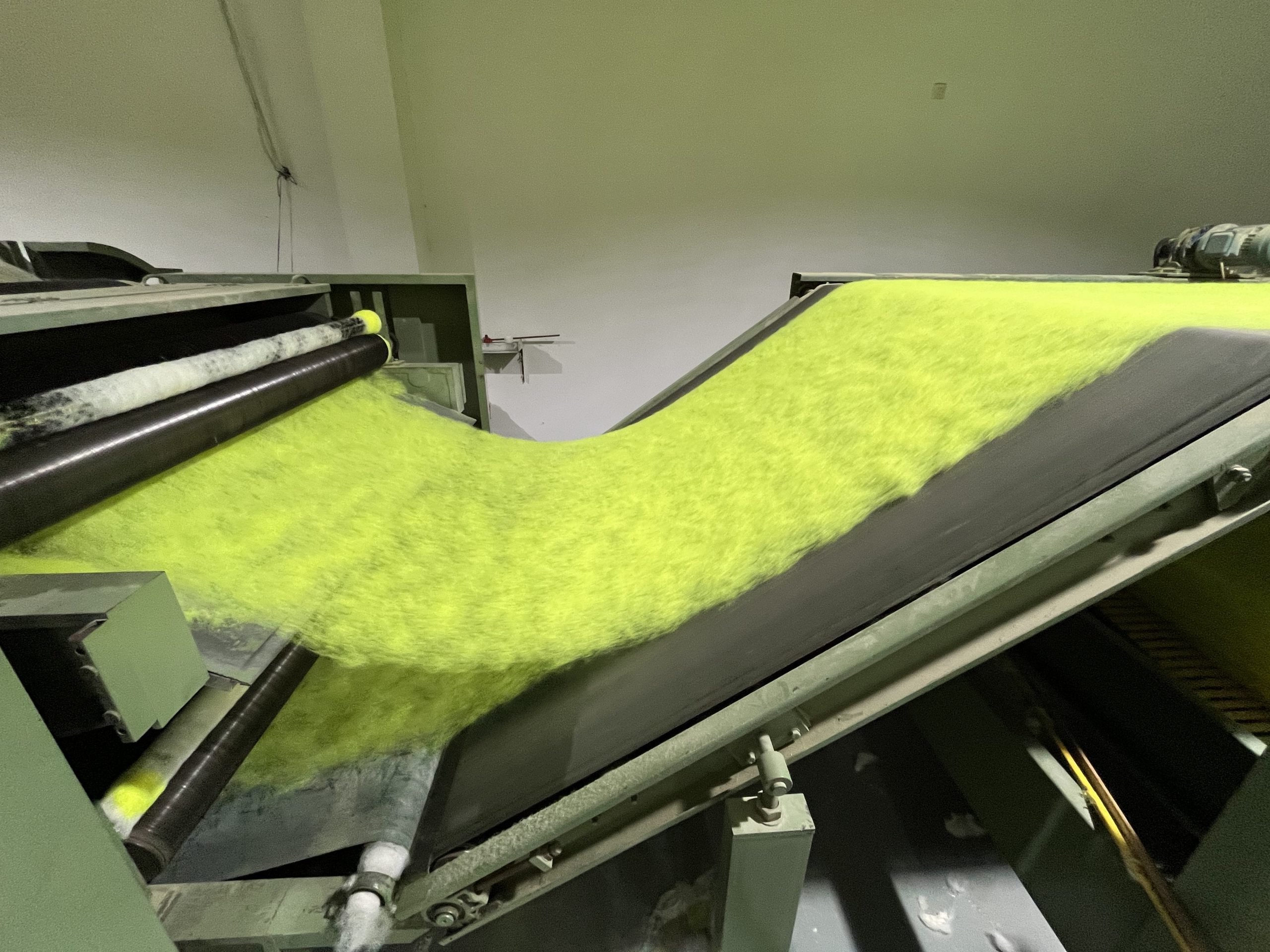

Web Laying Process

The carded fiber web proceeds to the next step

High-Speed Needling Process

Needle punching machines operating at up to 1200 strokes per minute ensure a perfect combination of internal density and external fineness in the felt

Finished Products

Finished Product Display

Cut and rolled according to the customer’s specific width requirements.

Finished tennis balls

Tennis balls made of Feirong felt are sold both domestically and internationally

Packaging and Shipping

Depending on the shipping conditions, the woven bags can be lined with a waterproof plastic bag

Production Video Clip